Toyota is often criticized for being “late” to EVs.

That criticism misses the point.

Toyota didn’t fall behind.

It refused to panic.

While many legacy automakers rushed into EVs after 2020, rewriting software stacks, reorganizing engineering teams, and burning capital,

Toyota did something unfashionable:

It protected its system.

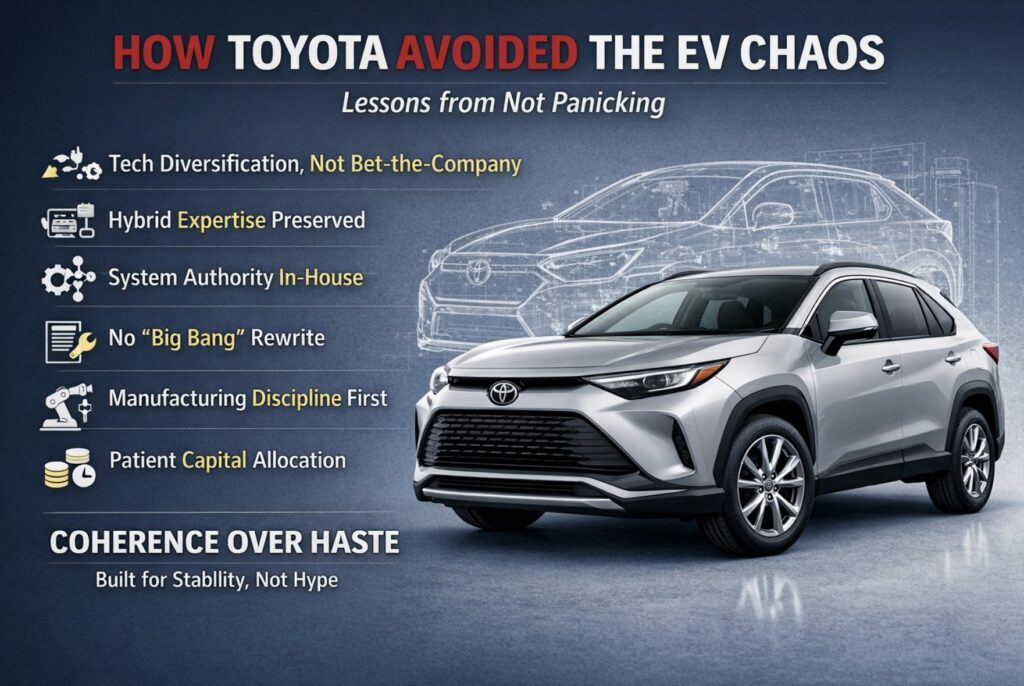

Here’s what Toyota did differently 👇

1️⃣ It never bet the company on one technology

Hybrids, PHEVs, EVs, even hydrogen, Toyota kept options open. That wasn’t indecision.

It was risk management.

2️⃣ Hybrids preserved powertrain and software competence

Hybrids are control-systems-heavy machines.

Toyota quietly built software, battery, and thermal expertise at massive scale without breaking reliability.

3️⃣ Toyota kept system authority in-house

Suppliers execute.

Toyota decides.

That single difference avoided the software dependency trap many OEMs fell into.

4️⃣ No “big bang” software rewrite

Toyota avoided the temptation to rebuild everything at once.

Incremental beats chaotic, especially in safety-critical systems.

5️⃣ Manufacturing discipline came first

If it couldn’t be built reliably at scale, it didn’t ship.

Demo-friendly ≠ production-ready.

6️⃣ Capital patience beat market pressure

Toyota stayed profitable while others chased headlines.

In industry transitions, time is the most valuable asset.

✅ The result?

Toyota may not look like the EV “leader” today,

But it avoided existential failures, protected its balance sheet, and kept its engineering system intact.

✍️The real lesson:

In technology transitions, speed matters.

But coherence matters more.

Sometimes the smartest move is not to be first, but to be impossible to destabilize.